OPT-SHOES

A Design Support Tool for Comfort Footwear

Footwear is one of the most widely and intensively used products influencing human comfort. OPT-Shoes is a simulation and computational “Computer-Aided Engineering” tool for the evaluation of footwear performance in terms of plantar mechanical comfort.

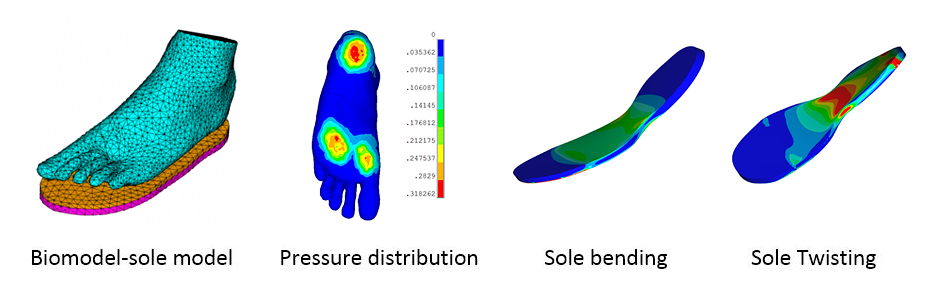

The tool is based on analytical finite element models (FEM) of shoe structures combined with a detailed biomodel of the human lower foot.

OPT-Shoes can be used to simulate and compute:

- Plantar pressures distribution on human foot in different gait stances

- Bending & Torsional properties of the sole structure

- Optimum sole structure (materials & thicknesses)

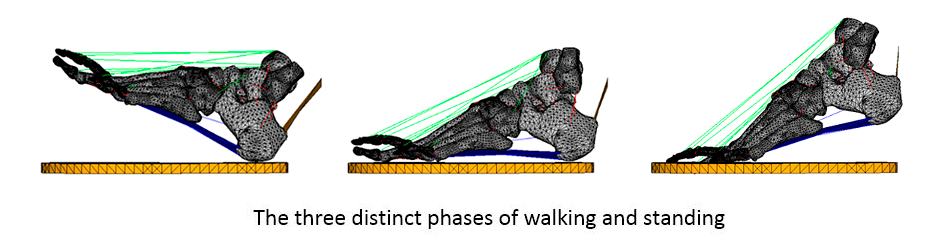

Plantar pressures analyses cover most types of occupational and low casual shoes subject to the effects of walking – standing positions (heel-strike, mid-stance, toe-off).

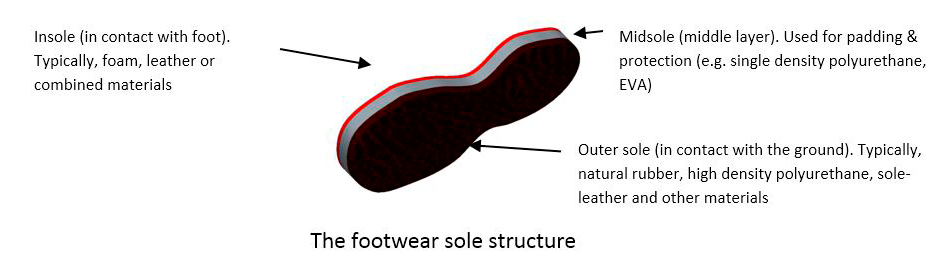

In OPT-Shoes, the sole is considered as a structure consisting of up to three flat layers: the outer (lower) layer that is in contact with the ground, the midsole layer and the inner (upper) insole layer that is in contact with the foot. Several combinations of industrial materials and thicknesses can be assigned to all three layers of the sole.

By registering you gain access to all available computational tools free of charge.

OPT-Shoes Web Tools Guide

Please consult the following video for a detailed guide on how to use our web service

More info: optshoes.syros.aegean.gr

Pressure

Plantar pressures are caused by the ground-to-body reaction forces due to the human weight and other movement related effects. Footwear intervenes between the plantar surface of the foot and the ground and its geometry...

Bending / Torsion

Bending and torsional comfort simulation is based on the assumption that the sole consists of three major layers of materials (e.g. polymer foam insole, EVA mid sole and butadiene rubber outsole)...

Optimization

Optimization is based on the very common product development case that thickness of each layer has been defined through geometric design and the intended product use determines the expected bending performance...